Pour Boy® Pour Spouts

The New Industry Standard

Pour spouts are the small yet sturdy backbone of the bar industry. Sometimes called liquor pourers, speed pourers, or bottle pourers, they are the unsung heroes behind every cocktail. And while they’re often overlooked, they’re crucial to any bartender or barista’s success and a "must have" to be added to your bar supplies.

Here at Crew Supply Co., we take pour spouts seriously (maybe too seriously). In fact, we’re proud to consider ourselves the geek squad of this product category. Why? Well, we have over a decade of experience behind the bar in various settings. We’ve experienced the frustration of pour spouts breaking during a packed happy hour or failing during peak volume. Trust us, we’ve been there and we know what it feels like to stop everything and dig for a functional spout while thirsty customers wait impatiently.

That’s why we devised a solution to this commonly felt pain point in the bar/restaurant industry (we also considered coffee shop and food applications, such as simple syrups, juices, dairy and non-dairy products) . Pour spouts have remained virtually unchanged for decades and we knew there had to be a way to innovate this barware essential.

Are you ready to learn everything you never knew you needed to know about pour spouts? We’re about to get knee-deep. Cheers!

What’s a Pour Spout?

Walk behind a bar and take a good look at the liquor bottles. They probably all have pour spouts on them. That’s because any bar owner or bartender worth their salt (rim) knows that pour spouts help you pour precisely, quickly, and cleanly.

How exactly do these little wonders work? The spout streamlines and directs the liquid leaving the bottle. That means faster pours, more control over where the liquid goes, and fewer spills.

When you’re trying to pour liquor into a jigger or shot glass, you want to fill it without wasting anything. The right pour spout can actually yield more cocktails per liquor bottle. Plus, quicker pours and less waste mean more profit!

Please note that although we focus on bartending uses in this blog post, pour spouts are also used in restaurants and coffee shops to serve beautifully garnished dishes and drinks.

The Evolution of Pour Spouts: Where They Came From and Where They’re Going

Bars have been around in America for a long time—since 1634, to be exact. Obviously, these establishments have changed quite a bit since then. Fast forward to the 20th century. Bars in the 1950s and early 1960s weren’t crowded or busy since only half of the population could frequent them.While men and women drank together in secret during the Prohibition era, laws were passed to “protect” women from the dangers of alcohol after it was legalized once again. It took until 1973 for most drinking establishments to be co-ed.

As bars evolved, so did mixologists’ tools, including pour spouts. Today, equipping bartenders with the right pour spouts (i.e., high-quality devices with an intelligent design) can mean the difference between serving mouthwatering drinks to run a successful operation and falling behind your competitors.

The Past of Pour Spouts

Until inventor John J. Daly applied for the first pour spout patent in 1963, bartenders kept the lids on bottles. John’s pour spout was a plastic, free-flow prototype.

After this invention, pour spouts began to find their way into nearly every bar in America in the 1970s, and they continue to be used across all different types of hospitality establishments.

Early Forms of Pour Spouts

Pour spouts as a concept have been around for as long as civilization. In Mycenaean Greece, for example, some jars had two spouts, one functioning and one non-functioning. Called “stirrup jars,” these squat vessels were used during the Late Bronze Age to export oils. While the spouts were part of the pottery itself, they undoubtedly inspired future iterations of the tool.

As for standalone pour spouts, archeologists have found some dating back to at least Late Medieval times. For example, they have recovered several copper alloy devices with decorative elements. These spouts date to the 15th century but may have been used well into the 16th century.

Historical Uses of Pour Spouts

Pour spouts have always been used to control the pouring of liquids. Whether built into the Ancient Greeks’ oil jars or placed inside the modern mixologist’s liquor bottles, these spouts channel the contents and regulate flow rate so pouring is cleaner, faster, and more precise.

Development of Pour Spout Technology

The earliest liquor pour spouts were free-flow prototypes made of plastic, which remains a popular material for them to this day. Plastic has always been affordable, accessible, and customizable. It’s easy to mold into the perfect ergonomic shape that fits into the neck of a standard 750-milliliter bottle.

As for Daly’s first speed pourer, the design hasn’t been improved much because it was such an ingenious device from day one. The patent states that he wanted to “provide a liquid pourer particularly adapted for liquor bottles so that a desired amount of liquor is dispensed in a uniform stream upon tilting of the bottle containing the pourer.”

Precision and speed were the two founding principles that influenced the design of the original pour spout. Before these spouts became widely available, bartenders simply removed the caps of the bottles every time they needed to pour a shot. However, this practice became unsustainable as bars became popular and the many thirsty patrons warranted faster service.

Pour spouts began to find their way into nearly every bar in America in the 1970s, and they continue to be used across all different types of hospitality establishments.

The Present of Pour Spouts

Plastic Pour Spouts

Plastic pour spouts are highly affordable, making them suitable for high-volume establishments. They’re also easy to clean and dishwasher safe. However, since these devices have various applications, it’s essential to confirm that the ones you buy for your bar or restaurant are made of food-grade plastic.

Metal Pour Spouts

Metal pour spouts typically cost more than their plastic counterparts, but they are more durable. They also have an added aesthetic element. Many mixologists think metal pour spouts look more professional, making for a sleeker bar.

Rubber Pour Spouts

Rubber pour spouts are a great compromise between plastic and metal. They’re affordable and durable, not to mention easy to clean. However, They lack the visual appeal of metal (or coated plastic), so they’re often reserved for bottles that aren’t visible from the customer’s perspective.

Glass Pour Spouts

Glass is another high-quality material for a liquor pour spout. Like metal devices, glass spouts can elevate a bar’s appearance. They’re also easy to clean, though they’re less durable than plastic or rubber devices.

Applications of Pour Spouts

Pour spouts are used in a host of industries. Let’s take a look at some of the most common applications.

1. Food and Beverage Industry

Considering they were initially designed for mixologists, pour spouts are primarily used in the food and beverage industry. In addition to making cocktails, these devices have been adapted for tasks like garnishing entrees, when precision and control are essential.

2. Chemical and Laboratory Settings

There are many scenarios in laboratory settings in which spill-free pouring is necessary. For example, researchers must be able to dispense hazardous chemicals with total accuracy when conducting experiments. Depending on the liquids in question, getting devices with additional features, like neck sealing rings, tempered glass, or PTFE coatings, may be necessary.

3. Industrial Applications

The industrial applications of pour spouts are limitless. From manufacturing to mechanics, there’s no shortage of scenarios in which small and precise amounts of liquid must be dispensed with total control. Like devices used in lab settings, those for industrial applications may demand features unique from the ones you’d find in food-grade pour spouts.

The Advantages of Pour Spouts

1. Precision

Pour spouts allow mixologists to measure liquids accurately while they work. Their consistent flow rate ensures the perfect ratio of ingredients every time.

Pour spouts allow mixologists to measure liquids accurately while they work. Their consistent flow rate ensures the perfect ratio of ingredients every time.

2. Efficiency

With calibrated spouts, bartenders can streamline their processes. Since they can pour and measure simultaneously, they can create more cocktails in less time.

3. Cost-Effectiveness

It’s virtually impossible to pour liquor from a standard bottle without spilling some. At the very least, the bartender will have to wipe up the dribble that runs down the neck of the bottle after it’s flipped upright again, no matter how steady their hand is. With help from a pour spout, on the other hand, you can create craft cocktails without wasting a single drop.

4. Cleanliness

Pour spouts make it easy to maintain a squeaky-clean bar environment. When installed properly, they prevent spills and mitigate the growth of bacteria. Furthermore, they can be tossed in the dishwasher or a sanitizing solution at the end of every shift so the spouts remain clean.

The Disadvantages of Pour Spouts

1. Additional Maintenance

Generally speaking, it’s wise to remove pour spouts at the end of the night. Pourers that have no caps subject the alcohol to oxidation, which reduces its shelf life and degrades its flavor. The tiny bit of liquid left in the spout can also attract insects because of its sugar content. For these reasons, it’s best to remove the spouts every night and recap the bottles while they’re being cleaned before replacing them at the start of the next shift. Since this will add to your team’s workload of opening/closing tasks, it’s arguably a drawback.

2. Limited Usage

Pour spouts can limit the creative control of the bar staff. Craft cocktails call for specific measurements—a quarter ounce here, a half an ounce there—making the measured pourer a hindrance in a cocktail environment. Not to mention the acclaimed "dealer's choice" in which a guest gives their bartender carte blanche to create a custom drink.

Common Components of Pour Spouts

Several different kinds of pour spouts are available today, and though each style is unique, there are commonalities. For example, every design takes these components into consideration in a unique way.

1. A Fin System to Fit a Variety of Bottle Neck Diameters

Nearly all pour spouts have a flexible fin system that adapts to fit different bottle neck diameters. Pour spout designs need to accommodate a wide variety of bottle neck sizes on the market.

2. An Air Tube System to Exchange Liquid for Air

By nature, pour spouts must have an air tube system that exchanges liquid for air when a liquid is being poured. An air hole sits outside the spout to take in the air. When you pour a liquid, the gurgling sound you hear is this exchange of fluid for air. This system plays a huge part in preventing leakage and maintaining air circulation inside and outside the bottle. If this hole is blocked, the flow of the liquor becomes slower.

3. A Tapered Spout to Channel the Flow

And, of course, they all have some type of tapered spout to channel the flow. A pour spout has a small tube that runs inside the pour spout to release the liquid.

SHOP POUR SPOUTS

The 5 Most Common Types of Pour Spouts

You might be wondering, what’s the best type of pour spout? Well, there’s no one-size-fits-all answer to that question, as it depends on the kind of setting and the goals of the business. For example, an intimate cocktail bar and a nightclub will have different operational needs and preferences when it comes to pour spouts.

Generally speaking, here are the five most common types of pour spouts, each with different pour speeds, precision, and durability. They all have advantages and disadvantages.

1. Free Flow/Standard Pourers

Free flow pourers are a busy bartender’s best friend. While other spouts have ball bearings or systems to control the flow of liquid, a free flow pourer lets the liquid flow smoothly and quickly, so you can get those cocktails to your thirsty patrons as fast as possible! However, with this type of pour spout, bartenders don’t have a precise way to measure the liquid that goes into a drink, so they must eyeball it. And if they continue to overpour, it can lead to a financial loss, as well as a potential liability concern about intoxicated patrons.

2. Angled Pourer

The angled pourer is also known as a tapered spout. It has a long, slim spout that helps bartenders pour liquor precisely and quickly. The tapered pour spout is accurate and allows consistent, high-flow rate pours. It’s easy to clean, but the open spout means this style is susceptible to fruit flies and other such nuisances. To make a drink, you have to have your bottle pointed in one direction and angle. You can also invert bottles completely. It’s an ergonomically limited pourer.

3. Screened Pourers

Are you worried about fruit flies and no-see-ums getting drunk on your dime? A screened pourer can help with these pesky critters, so it’s a must-have for outdoor bars. However, they’re not good for creamy, high-viscosity liquids. The screen slows the flow rate, which makes it take longer to pour a drink. And imagine pouring a creamy liquid like Bailey’s or syrup through this type of pourer—it’s even slower than other less viscous fluids. They’re not a good option for fast-paced environments. Plus, they’re quite difficult to clean due to the tiny holes.

4. Measured Pourers

Measured pourers are engineered with a mechanical ball-bearing system to control consistency, prevent over-pouring and keep bartenders honest. These pourers work like a valve: they open to allow a certain amount of alcohol to pass through based on their set capacity and then shut off to prevent over-pouring. Measured pourers are popular in ultra-high-volume venues (think nightclubs and sports stadiums) where consistent pouring and profit margins are vital.

A downside to these measured pourers is that since they come in set sizes, it’s up to the bartender to know which one to grab, which can be a challenge on a busy night.

5. Plastic, One-Piece Pourer

The plastic, one-piece pourer is just that. It’s a common pour spout for bars, as it’s a durable piece with just one part. Bartenders can freely pour alcohol, which is good for fast-paced environments. On the other hand, free-flowing pour spouts can lead to over-pouring, resulting in a financial loss and potential liability. These pour spouts don’t have any protection, so they’re susceptible to bugs.

The Evolution of Pour Spouts

Bars have been around in America for a long time—since 1634, to be exact. Obviously, bars have changed quite a bit since then. Fast forward to the 20th century. Bars in the 1950s and early 1960s weren’t crowded or busy since only half of the population could frequent them. While men and women drank together in secret during the Prohibition era, after alcohol was legalized once again, laws were passed to “protect” women from the dangers of alcohol. It took until 1973 for most drinking establishments to be co-ed.

There really hasn’t been any innovation in pour spouts since the measured pourer. Until now. Here at Crew Supply Co., we have first-hand experience with the challenges that bartenders face. With over a decade of craft bartending experience under our belts, we understand customer pain-points, and we can relate deeply to the problems that cause headaches for busy bartenders. We’ve dealt with cheap, disposable bar supplies that fell apart. We’ve felt the pressure as the bar starts to fill up, and we can’t find the right liquor bottle. And we’ve felt the lack of innovation and drive to help us create a better solution.

So, we set out to build a better pour spout ourselves. At Crew Supply Co., we worked with hundreds of bartenders to create, develop and test pour spouts. And input from our customers says we’ve nailed it.

Our Pour Boy® Pour Spout was developed by industry-leading bartenders to strike the perfect balance between form and function. It’s the most modern and innovative pour spout on the market, and it takes John Daly’s design to the ultimate level.

So, what sets our Pour Boy® Pour Spout apart from the rest? Read on to learn more.

Until inventor John J. Daly applied for the first pour spout patent in 1963, bartenders simply kept the lids on bottles. John’s pour spout was a plastic, free-flow prototype.

After this invention, pour spouts began to find their way into nearly every bar in America in the 1970s, and they continue to be used across all different types of hospitality establishments.

Since the original use of pour spouts in bars, many other types have come on the market. You can opt for plastic or metal, and many spouts have two or three ball bearings inside the pourer to regulate liquid flow. In addition, they’re frequently used for liquids that are non-alcoholic, such as for syrups and juices in coffee shops and for liquids like salad dressings in restaurants.

The Last Major Innovation: the Ball-Bearing Mechanism

The last major innovation in pour spouts was when the ball-bearing mechanism came along. As we described previously, this mechanism functions as a valve, which causes the flow to stop after a certain amount of alcohol passes through. The goal was to prevent over-pouring, resulting in a profit loss. It also was trying to limit potential liability, as heavy pours can lead to intoxication.

The design had good intentions; it has its limitations though. Bartenders can overcome the limit by simply turning over the bottle again to make a stronger drink, leading to both things that the design was trying to achieve. One of the current trends in bartending is craft cocktails, in which bartenders need more flexibility with each pour due to recipes calling for as little as ¼ oz of a liquor. So a measured pourer is basically useless in a craft bar environment, which is in virtually all bars now.

Why the Lack of Innovation?

We think there’s been a lack of innovation for a few reasons. The pour spouts on the market today are inexpensive, so many bar owners/operators continue to just buy more and don’t think about the longer-term impacts of these purchasing decisions.

Also, as in many jobs, bartenders tend to have to make do with the tools that they have, and they aren’t asked to seek out ways to improve workflow and efficiency.

Here at Crew, we view things differently. We look at bar tools through the eyes of the industry professional. We’ve been there. We know what kind of tools we wished that we’d had. So we decided to do something about it. Read on to learn more.

Taking a liquor pour spout out of a snug or sticky bottleneck can be a pain. Literally. And the last thing you want to do is fight with a pour spout and take care of a wound when you have customers waiting. Our competitors have a 2-component design consisting of polymer and steel elements, which aren’t securely attached to each other. When a bartender goes to remove this type of design, the steel element can separate from the polymer element, rendering the product virtually useless. This is a huge pain point for bartenders.

Our liquor pour spout has an over-molded design, which is one unit, so the pour spout won’t come apart when you remove it from a bottleneck. This design is more comfortable for bartenders’ grips, as their fingers/thumbs aren’t exposed to sharp steel. So they’re safer and more hearty, resulting in fewer injuries and replacements. And, you’ll see long-term savings since you don’t have to replace them as often.

Don’t worry about your Pour Boy falling apart when you remove it from the bottle. The Pour Boy spout is ultra-durable and can handle even the toughest wear and tear.

2. Available in Multiple Colors for Better Organization and Identification

If you've ever worked as a bartender on a busy shift, you know that the environment can be chaotic.

Picture this all-too-common situation. It's 9:30 pm on a Friday night, and the bar is in full swing. Drink orders are flying in faster than you can field them. The music is loud, servers are waiting for drinks and guests are growing increasingly impatient. You are—as we say in the industry—in the weeds.

Now, if you were pouring shots and beers, this wouldn't be too much of a challenge. But these guests want craft cocktails—Gimlets, Sidecars, Juleps and house cocktails (remember the one YOU created with egg whites?). Not only do you need to craft these cocktails with speed and precision, but you must also do it with a smile on your face all while maintaining eye contact with your customers and fielding additional orders. At this point, if you're not organized, things can go from bad to worse in a hurry.

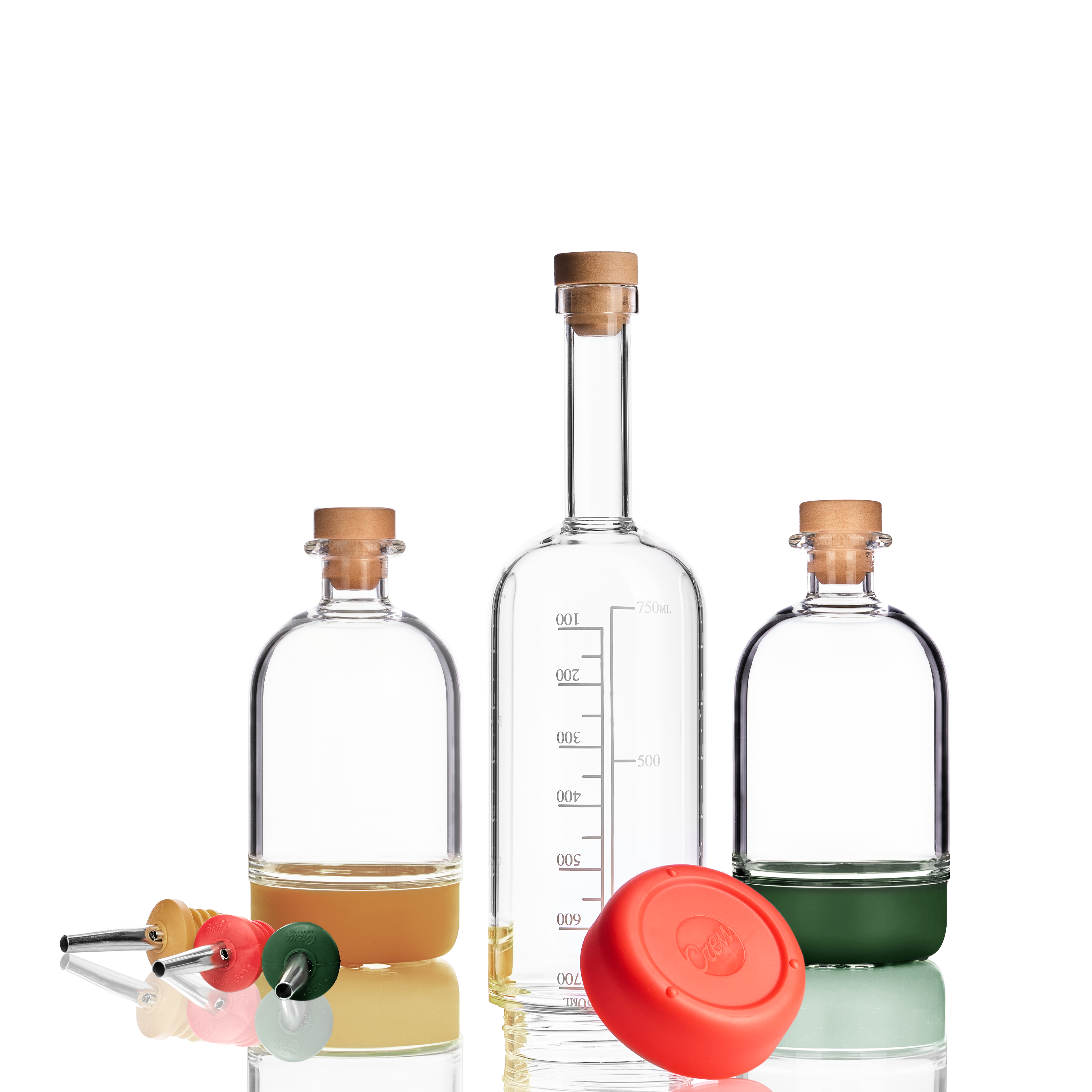

Our color-coded organization/pour spout system allows bartenders to instantly identify ingredients from a birds' eye view. Craft bar programs use Pour Boys® to create a "cockpit" feel in their prep stations so that bartenders always feel organized and efficient. To make your organization complete, we also have leak-proof syrup and juice bottles that match our colorful collection of pour spouts. Think an orange Pour Boy and durable Craft Tech® Glass bottle for your OJ, a red Pour Boy and bottle for tomato juice, and so on. You can create an organization that fits best for the way your business works.

Let's face it, there will always be chaotic moments in bartending. But by creating an organized, color-coded labeling system, bartenders can increase efficiency and feel more confident behind the stick. As a result, you’ll have happy customers, resulting in more sales and repeat customers.

3. Adaptability

The greatest pour spout in the world won’t help you if it doesn’t fit your bottles. And given the array of bottles on the market, there’s no such thing as a “one size fits all” solution.

That being said, our adaptable fin system was developed by seasoned bartenders to create the most ubiquitous design on the market. We worked with hundreds of different bottleneck sizes to determine the most universal dimensions for the Pour Boy® Pour Spout. The Pour Boy® Pour Spout works in most standard liquor bottles and fits more bottle sizes than any of our competitors.

4. Easy to Clean

When you’re working behind a bar, nothing is more important than maintaining a squeaky-clean environment. Bar tools should always be well-groomed, especially those that come in direct contact with drink ingredients. That’s why we incorporated an innovative over-molded design, which prevents bacteria from building up in small cracks and crevices.

And when it comes time to clean our pour spouts, simply toss them in the dishwasher or a sanitizing solution overnight, and then reapply them the next day. Good as new.

5. Perfect Flow Rate

Not to brag, but we really nailed this one. To arrive at our design, we spent years comparing and contrasting the flow rate of existing pourers to determine the ideal speed for precision pouring in a high-volume environment. And “we” means seasoned bartenders who tested and tweaked it until we got the perfect flow rate for high-volume craft cocktail bartending. The result is a high-quality speed pourer that industry professionals love.

Innovations in Pour Spout Design and Technology

The last major innovation in pour spouts was when the ball-bearing mechanism came along. This mechanism functions as a valve, which causes the flow to stop after a certain amount of alcohol passes through. The goal was to prevent over-pouring, resulting in a profit loss. It also was trying to limit potential liability, as heavy pours can lead to intoxication.

The design had good intentions, but it has its limitations. Bartenders can overcome the limit by simply turning over the bottle again to make a stronger drink, leading to both things that the design was trying to achieve. One of the current trends in bartending is craft cocktails, in which bartenders need more flexibility with each pour due to recipes calling for as little as ¼ oz of a liquor. So, a measured pourer is basically useless in a craft bar environment, which is in virtually all bars now.

Since the original use of pour spouts in bars, many other types have come on the market. You can opt for plastic or metal, and many spouts have two or three ball bearings inside the pourer to regulate liquid flow. In addition, they’re frequently used for liquids that are non-alcoholic, such as for syrups and juices in coffee shops and for liquids like salad dressings in restaurants.

Increasing Sustainability and Eco-Friendliness

Pour spouts allow bars and restaurants to operate in a more sustainable way. By eliminating waste, they decrease the amount of inventory these establishments must order. This, in turn, reduces the number of deliveries that vendors have to make, shrinking the industry’s carbon footprint in the process. When you consider the ripple effects that deploying pour spouts can have, it becomes clear just how eco-friendly they are.

Trends of At-Home Applications

Because of their precision and accuracy, high-quality pour spouts are one of the most important tools for making complicated craft cocktails. And because they’re available to everyone, it’s never been easier for mixology to go mainstream. Once people realized they could make mouthwatering cocktails at home as long as they had the right tools, there was no going back. The availability of pour spouts from businesses like us and not just restaurant suppliers proliferated this trend.

The pandemic definitely spurred a home mixology movement, and it’s since become clear that it’s here to stay. Regardless of whether you’re a longtime hobbyist or you only just started getting creative with cocktails, though, you can stock up on all the essential tools for your own bar on our Crew Home website.

Cross-Functional Applications at Home

Pour spouts are a great tool for those who want to get creative in the kitchen, as well. They can be used to make infused liquids for coffee beverages and desserts, for example, or to dispense olive oil for dipping fresh-baked bread or making salad dressing. Whatever your need for pour spouts, consider getting the 850ml leak-proof durable glass bottle, as well, for mixing, storing, and pouring all your favorite liquids.

Stock Your Bar with Top-Quality Pour Spouts

Pour Spouts have revolutionized mixology, and their functionality has made them irreplaceable in many other applications, as well. There’s no better tool to use when you have to dispense liquid with control and accuracy.

While the kinds of devices available today are incredibly versatile—there is a spout for every job—there’s no doubt that they will keep evolving as their applications expand. You can be sure Crew Supply Co. will be at the forefront of the evolution!

We hope you’ve enjoyed reading our pour spouts as much as we enjoyed writing about them! And yes, we’re proud to be the unofficial nerds of the pour spout world! Check out our entire Pour Boy Pour Spout collection, as well as our juice bottles and other bartending tools. If you have any questions, please reach out to us at support@crewsupplyco.com.

Frequently Asked Questions

What is a pour spout?

A pour spout is a small device that is attached to the neck of a bottle to control the flow of liquid. Pour spouts are often used in bars and restaurants to help bartenders pour drinks quickly and accurately. They can also be found in labs and industrial settings.

What are the benefits of using a pour spout?

There are several benefits to using a pour spout. Pour spouts can help to:

- Reduce over-pouring, which can save money and prevent waste

- Improve the accuracy of pours, which can lead to better-tasting drinks

- Make pouring drinks faster and easier

- Prevent spills and messes

- Keep bottles clean and sanitary

What are the different types of pour spouts?

Several different types of pour spouts are available, each with its advantages and disadvantages. Some of the most common styles include free flow pourers, angled pourers, screened pourers, and measured pourers.

How do you clean a pour spout?

Pour spouts should be cleaned regularly to prevent the buildup of dirt, bacteria, and mold. To clean a pour spout, simply remove it from the bottle and wash it with soap and water, soak it in a restaurant-friendly sanitizing solution, or toss it in the dishwasher.

Can you leave pour spouts on bottles 24/7?

When dealing with liquids that will be consumed, like alcohol and simple syrup, it’s best to remove the pour spouts periodically and wash them. Many bars do this at the end of every night. This will keep insects at bay and prevent bacteria from accumulating in the dispenser. Recapping the bottles after each shift can also extend the shelf-life of the liquids they contain.

Share:

Pour With Pride: Bigger Than Bar Supplies

Eco Straws: A Restaurant Buyer’s Guide to Plastic-free Bar Supplies